Accurate sampling is a core requirement for any well-run minerals operation. Having results you can trust allows you to make better process and quality control decisions for your business.

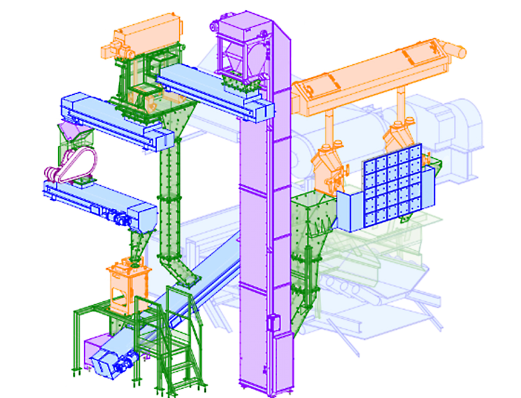

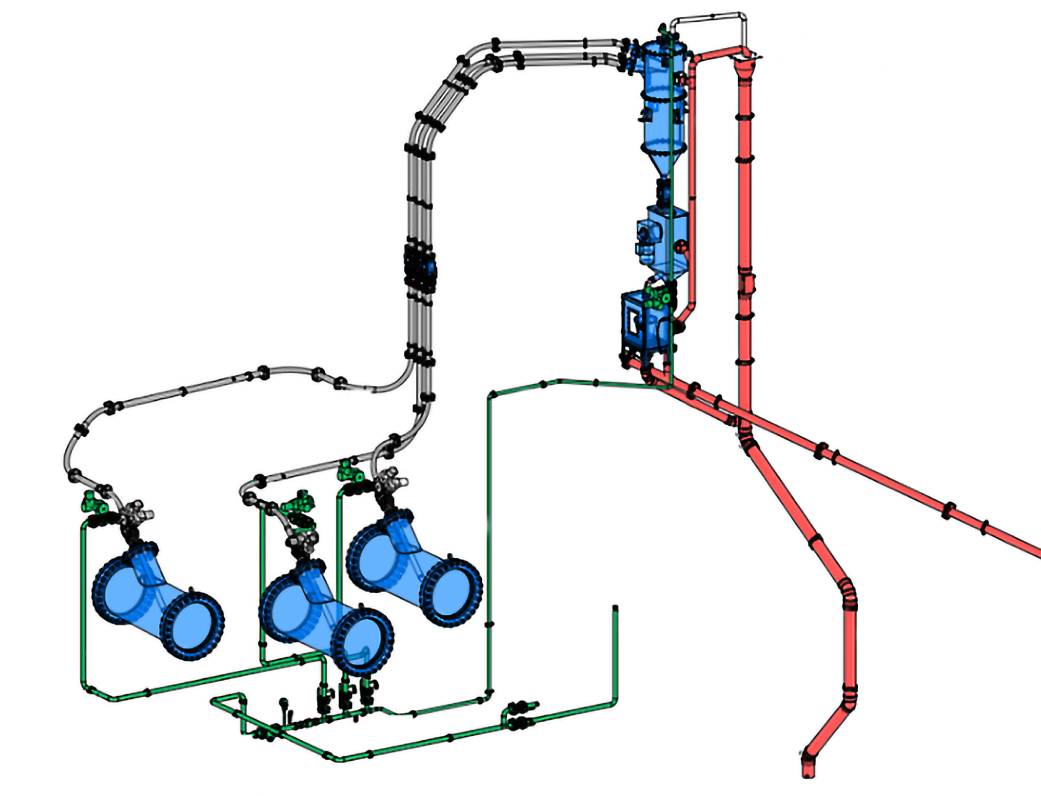

We have been supplying sampling systems to the mining and cement industries for many decades. That is decades of product development and decades of listening to feedback from customers. Our engineers have used that experience and knowledge to build a range of sampling systems suited to the needs of modern operations – starting from basic engineering process till

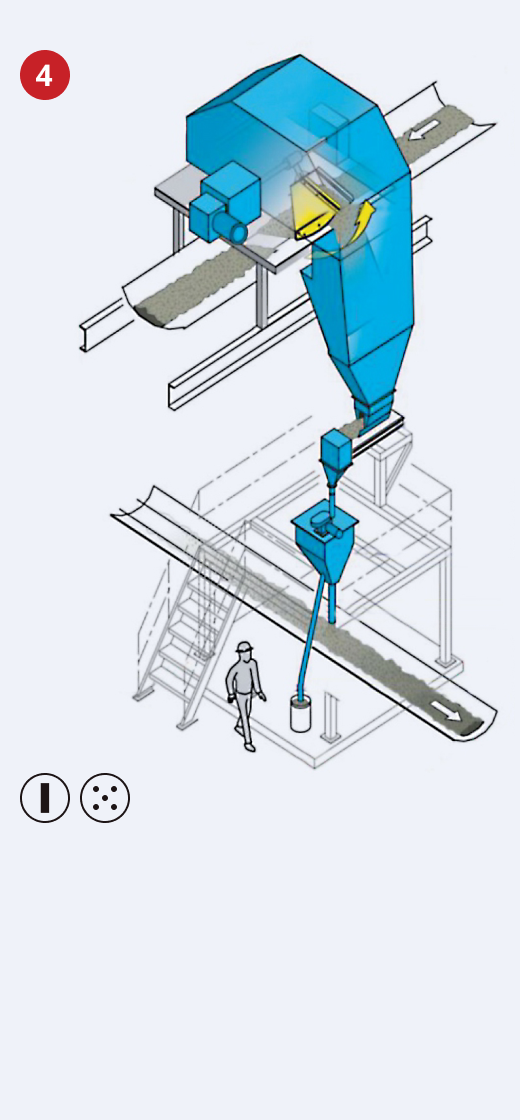

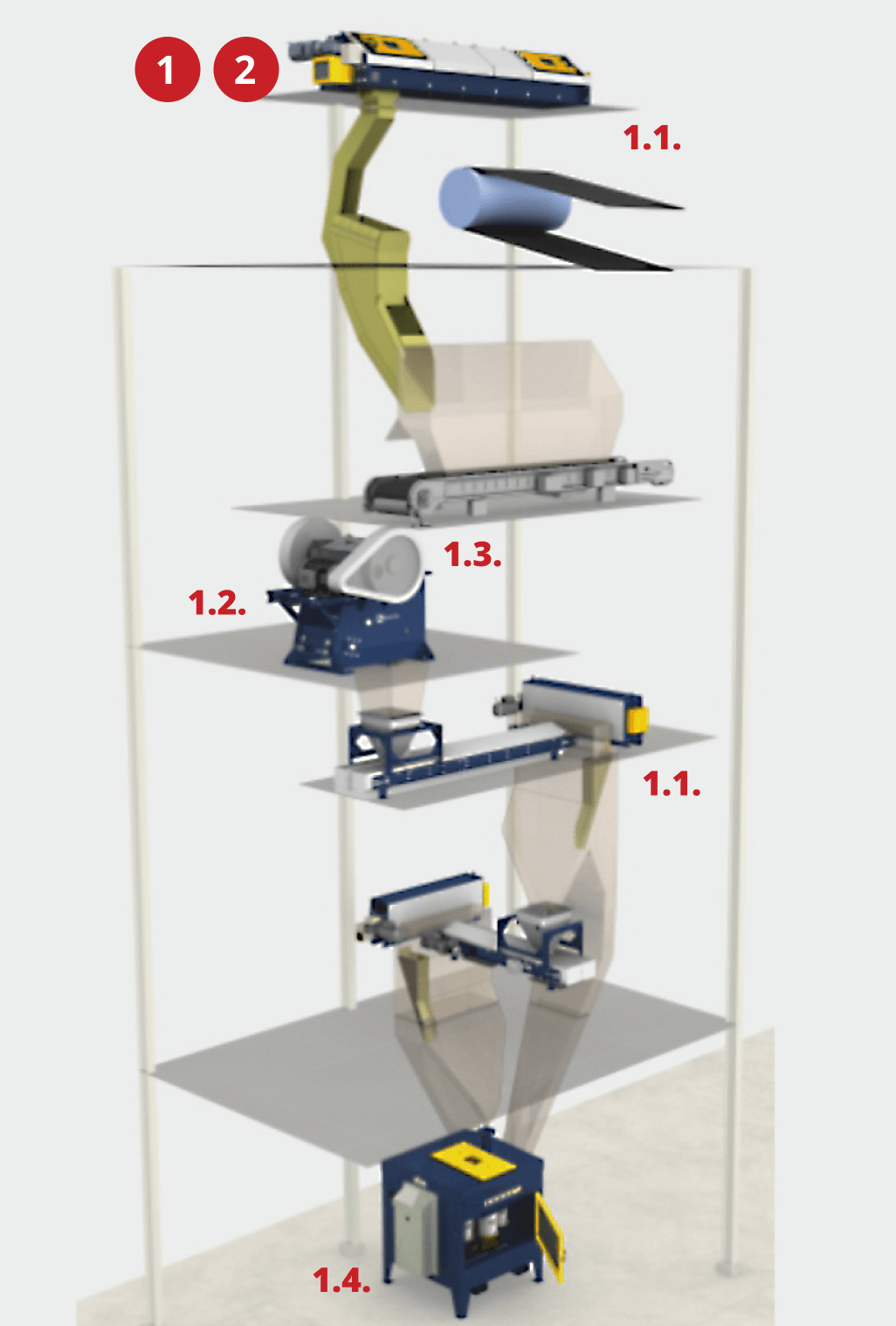

Used to take a primary sample from the main technology line. Smaller models to take secondary/tertiary samples inside sampling tower.

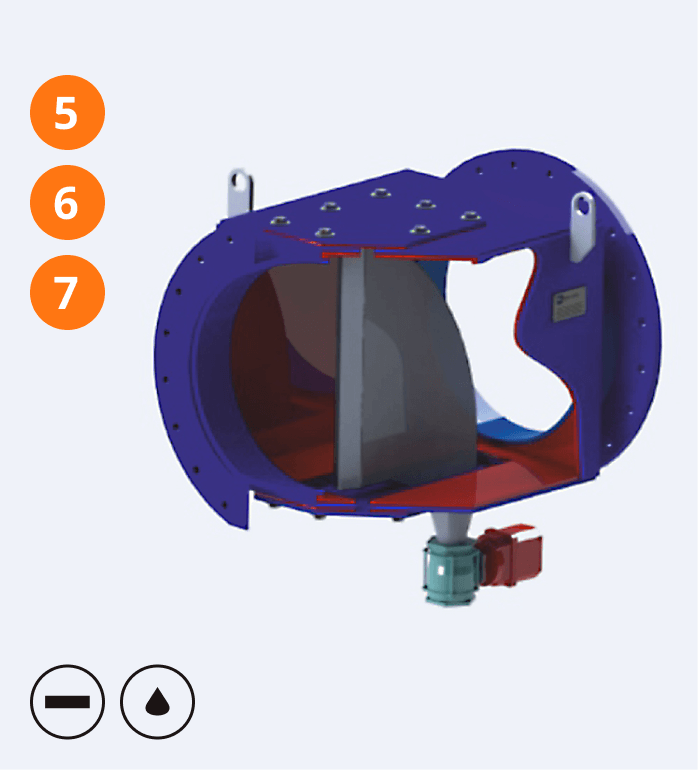

Used to reduce lumps size on continuous basis. Robust design and heavy duty assembly for industrial use.

Used for accurate materials feeding for crushing or dividing. Supplied with hopper, frequency converter and covered conveyor.

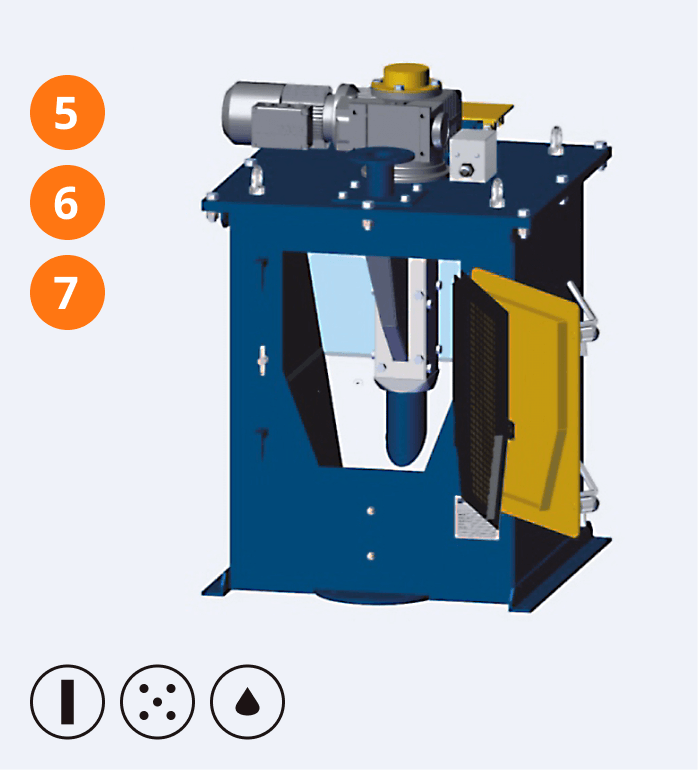

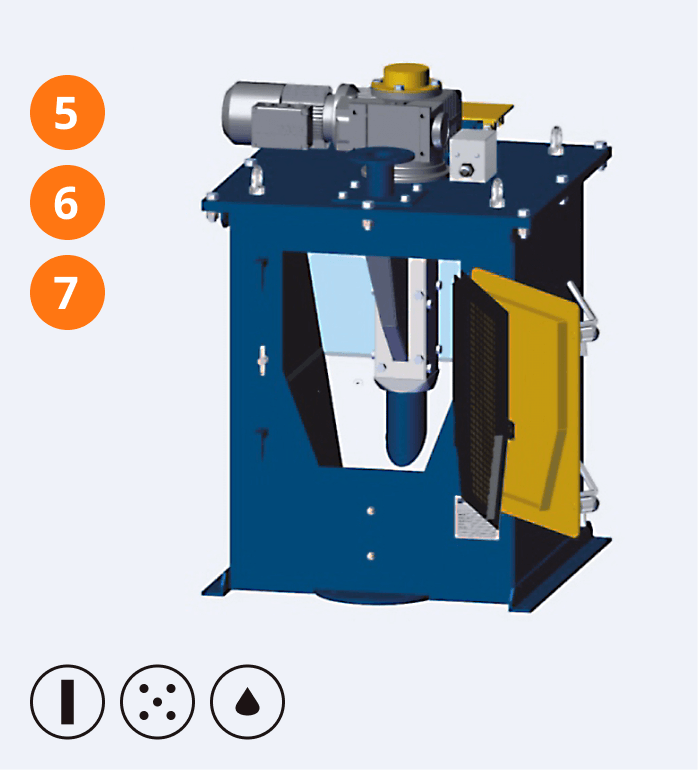

Used to collect representative sample during the sampling procedure (lot, time basis).

• Rotary collector

(up to 8 cans)

• Linear collector

(2 cans)

• Single collector

(1 can)